Congratulations to First Tyre Successfully Made from 85” Tyre Vulcanizing Machine and matching Mould of Sichuan Tire & Rubber Group

- Categories:Company news

- Author:

- Origin:

- Time of issue:2020-11-24 16:30

- Views:

Congratulations to First Tyre Successfully Made from 85” Tyre Vulcanizing Machine and matching Mould of Sichuan Tire & Rubber Group

- Categories:Company news

- Author:

- Origin:

- Time of issue:2020-11-24 16:30

- Views:

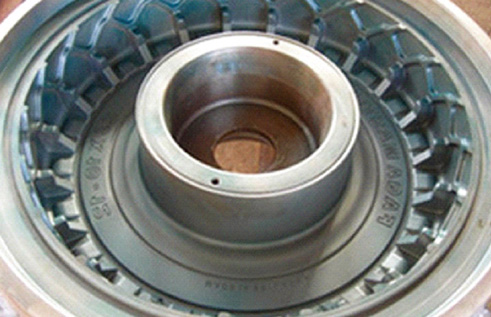

Our company developed and produced 1 set of 85” steamer type engineering tyre water hydraulic vulcanizing machine and matching engineering tyre mould 26.5-25 and tyre building drum 26.5-25 for Sichuan Tire & Rubber Group. Now the85” Tyre Vulcanizing Machine and matching mould has been installed and the trial operation is successful! The first engineering tyre made with this 85” Tyre Vulcanizing Machine was off the assembly line! This is currently the largest tyre produced by Sichuan Tire & Rubber Group.

This Tyre Vulcanizing Machine is applicable to vulcanize all-fiber engineering tyre (OTR) and agricultural tyre with automatic and manual control functions. Using this machine, users can achieve the production process of rubber tyre from unvulcanized rubber green tyre, including tyre loading, shaping and vulcanizing, tyre unloading, and so on. The whole process can achieve single machine automatic cycle.

This Tyre Vulcanizing Machine is single-mould water hydraulic horizontal moving tyre vulcanizing machine, which is composed of host machine, tyre loading and unloading mechanism, electric control system, central mechanism, power water control system, vulcanizing pipeline system. The mould is heated by steam cabinet. And the upper mould first rises vertically and then moves backward in the mould opening movement. The central mechanism is BOM type. The machine is equipped with manipulator to complete the tyre loading and unloading. The front can back movement of the upper steam chamber is driven by a variable frequency motor, and the start and stop are set with acceleration and deceleration time to ensure the smooth operation of the translation frame. The other actions are driven by water cylinders, no mechanical friction, no lubrication system, simple use and maintenance, and saving operating costs.

We are a manufacturer of tyre equipment, the main products are: Tyre Vulcanizing Machine (including both Mechanical & Hydraulic Tyre Vulcanizing Machine, All-Steel Giant Tyre Hydraulic Vulcanizing Machine, etc.), Tyre Building Drum, Tyre Mould, Tyre Post Cure Inflation Device, etc. Our All-Steel Giant Tyre Vulcanizing Machine (95-212 inch tire vulcanizing machine) and All Steel Giant Tyre Segment Mold (27R49 to 59/80R63) have been used in many domestic tyre companies and have got recognition and praise from them.

Scan the QR code to read on your phone

Relevant Information

NEWS CENTER

CONTACT US

QINGDAO FANGYUANDA RUBBER MACHINERY CO., LTD

Phone:13792882828

Tel:0532-87879188

E-mail:helenliu@fangyuanda.com

Add:Hui'an Road, Airport Industry Park, Chengyang District, Qingdao City, Shandong Province, China

WeChat Contact QR Code

Official website QR code

Copyright © QINGDAO FANGYUANDA RUBBER MACHINERY CO., LTD 鲁ICP备14010060号 Powered by www.300.cn

Copyright © QINGDAO FANGYUANDA RUBBER MACHINERY CO., LTD